October 15, 2025

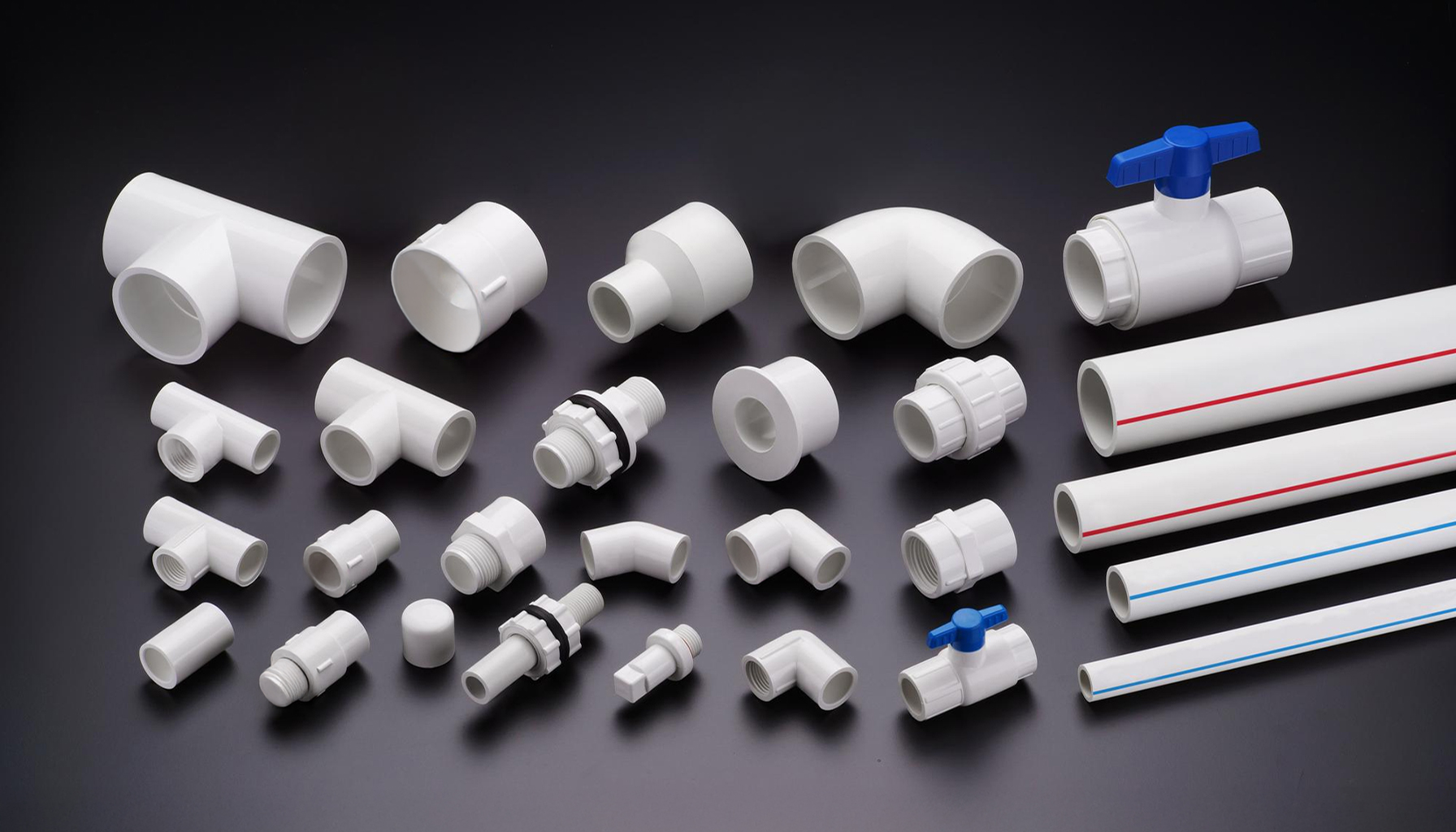

When projects go over budget, the culprit is rarely the last tap set. It is usually mismatched pipes and pipe fittings, vague specifications, and cross-brand compatibility issues.

Indian buyers comparing pipes and fittings need a practical, engineering-led way to shortlist materials, pressure classes, and jointing systems that stay leak-free, resist hard-water abuse, and install fast with minimal rework.

This guide lays out a commercial checklist to make comparisons fair and procurement predictable, with Watertec highlighted where it helps close the loop from spec to service.

Which material for India: match water quality, temperature, and layout

Different projects need different behaviours from pipes & pipe fittings. For hot plumbing in apartments and villas, CPVC offers temperature resilience, low scaling, and reliable solvent-weld joints. For cold-water distribution and vent lines, uPVC gives stable economics and clean internal surfaces for good flow.

For concealed lines exposed to vibration or external runs in coastal or industrial zones, look at polymers with proven corrosion resistance and UV stability. Always map the material choice to inlet pressure variability, water heater outputs, and fixture concurrency so pipes and fittings preserve both flow and safety margin.

Sizing and pressure class: protect flow and joints

Choose the diameter to control friction loss first, then select the pressure class to protect joints under peak conditions. Booster pumps, rooftop tanks, and municipal surges can push transient pressure far above “steady” numbers. In hot lines, apply temperature derating to the working pressure so the class that looks safe at ambient still holds up at geyser temperature.

If two or more showers may run at the same time, upsizing the diameter often saves pump energy and avoids whistling and hammering. A simple rule that prevents callbacks: size for peak, and class for peak-at-temperature.

Jointing systems: speed, strength, and serviceability

Solvent-welded CPVC joints are fast and reliable if the SOP is followed. Square cuts, inner and outer deburring, dry-fit depth marking, correct solvent-cement viscosity, full-socket insertion with a quarter-turn, and cure windows by ambient temperature. For threaded transitions, keep metal threads on the metal side with appropriate sealant, and keep the polymer side strictly as designed.

In pump rooms and plant areas, union valves and union fittings shorten shutdowns and protect maintenance budgets. Reliable pipes and fittings are as much about the method as the material.

Compatibility and one-system procurement

Most leak stories begin with mixing brands. Build a single-system bill of materials that ties pipe schedule, elbows, tees, reducers, transition fittings, valves, supports, and the approved solvent cement and primer to one validated family. Insist on printed install guides, cure-time charts, and warranty terms with batch numbers documented on the delivery note.

This is where Watertec’s system-led approach helps procurement teams avoid grey compatibility zones and keeps installers aligned to one clear SOP from first joint to hydro test.

Hard-water realities: design for low maintenance

Indian hard water accelerates scale and stains, but smart choices mitigate this. Smooth-bore polymer pipes limit scale adhesion and keep velocities stable over time. In hot lines, a balanced loop with isolation valves near heaters simplifies periodic flushing. At fixtures, aerators that resist clogging protect the feeling of pressure without increasing consumption.

Over a multi-year horizon, the right pipe & pipe fittings choice equals fewer chemical cleanups, fewer noisy lines, and cleaner fixtures for longer.

Installation QA: test before tile

A clean hydro test is less expensive than re-tiling. Pressure-test in sections after proper cure windows, record pressure and ambient temperature, and hold for the specified duration. Photograph witness marks and bead lines at representative joints before closure. Label circuits and leave an access route at critical valves.

This discipline is what turns good materials into reliably quiet, leak-free systems.

Why shortlist Watertec for pipes and fittings?

Watertec focuses on coordinated pipes and fittings with clear compatibility guidance, solvent-weld SOPs, and practical install checklists tuned for Indian sites. System-matched components, precise moulding, and documented cure and test protocols reduce rework, keep lines quiet, and keep finishes clean.

For commercial buyers, that means fewer surprises between RFQ and handover, and tighter control of lifetime maintenance costs.

Conclusion: specify by behaviour, not buzzwords

Start with site realities, not catalogue slogans. Pick material by water quality and temperature, size for flow first, then select pressure class for peak-at-temperature safety. Lock in one-system compatibility for pipes and fittings and enforce a simple, repeatable jointing SOP. Test before tile and document the baseline so service stays quick and predictable.

To move from comparison to closure with confidence, build a matched BOM with Watertec, review compatibility, and book a hydro-tested installation plan that delivers performance from day one.

Next steps

Build a system-matched BOM for pipe & pipe fittings with compatibility confirmed

Request sizing and pressure-class recommendations for hot and cold lines

Book a hydro test and commissioning checklist for faster handover